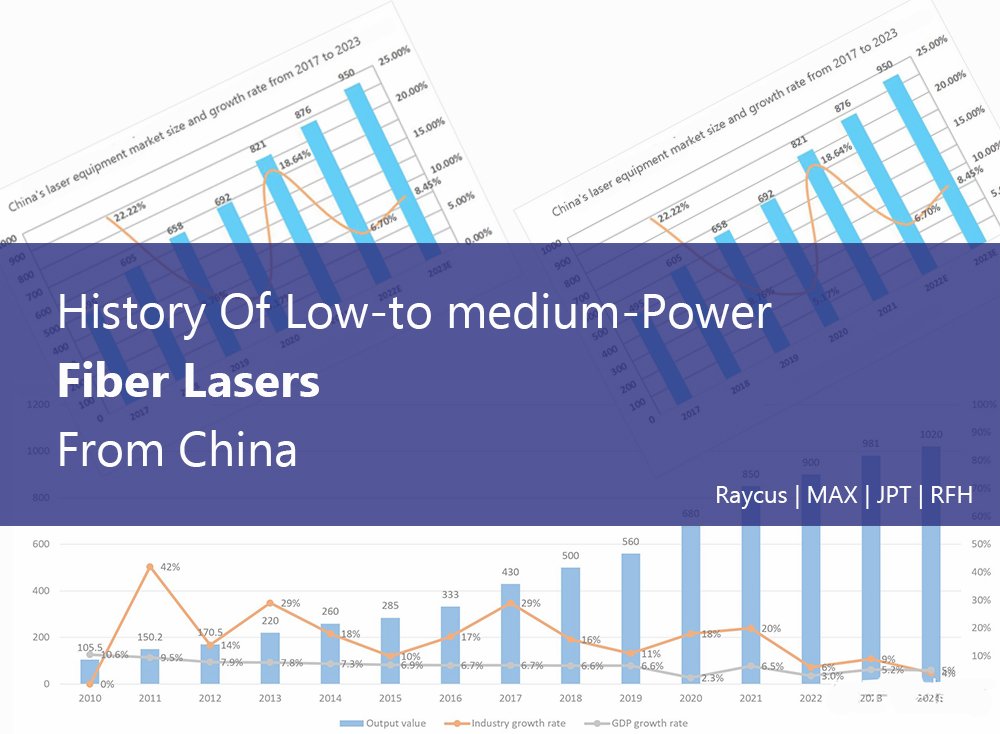

Introduction: market share of fiber lasers made in China

In 2003, IPG sold the first Q-switched pulse fiber laser in China. This officially opens up the application of fiber lasers in Chinese manufacturing. Meanwhile, fiber lasers have been developed and manufactured in China for over 20 years. According to the “2024 China Laser Industry Development Report”, in 2024,MAX Laser has successfully ranked first in the revenue ranking of fiber laser companies in China. This has surpassed the former industry leader IPG and become the largest domestic manufacturer in terms of market share.

Part 1: At the beginning, Chinese laser equipment manufacturers relied on imported "luxury goods"-- fiber lasers。

At the beginning of the 21st century, China’s manufacturing industry was developing rapidly. But most enterprises could only afford to use this advanced laser processing technology. Why? One key reason is that laser equipment is too expensive and inconvenient to maintain.

At that time, almost all of the fiber lasers needed in China’s industrial sector relied on imports from international giants such as IPG. A low-power laser can cost tens of thousands or even hundreds of thousands of dollars. In addition, there are high post maintenance costs and long waiting periods for parts.

This has brought some issues. Firstly, the high cost of core fiber lasers directly leads to the high overall cost of laser equipment.Secondly, technical services are restricted. When there is a problem with the machine, the laser equipment manufacturer does not have the ability to repair it. All they can do is wait for the original factory engineer to handle it. This greatly affects the production and use of the equipment.

So, laser technology can only be applied to a few high profit industries. It cannot be popularized in small and medium-sized manufacturing industries.

Part 2: The initial stage of fiber laser production and manufacturing

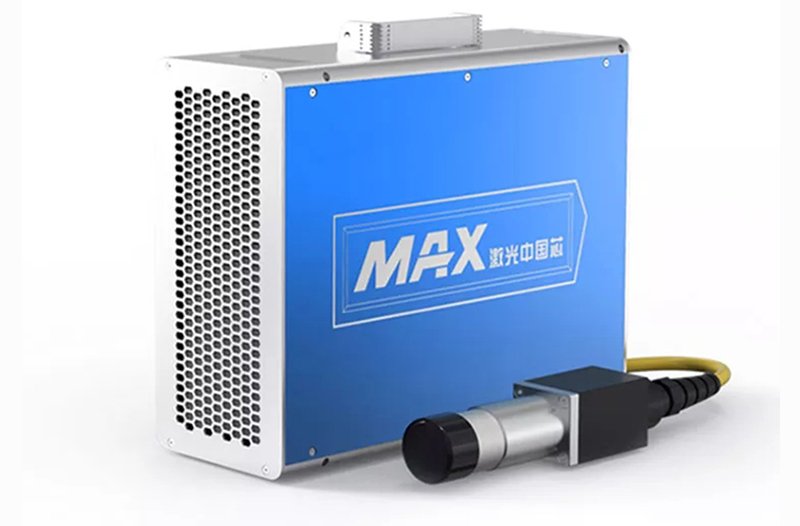

The first batch of fiber laser enterprises in China, represented by Raycus Laser and Max Laser, were successively established after 2000.Their goal is very clear: to create China’s affordable industrial fiber laser.

They started with the basic components of fiber lasers. From isolators, pump sources, combiners to fiber Bragg gratings, they develop them component by component. Since 2007, the research and development achievements of fiber lasers have begun to emerge. The enterprise has gradually achieved independent research and production of these core optical components.

Part 3: The explosive growth of the laser application market.

After the core components of medium and low power fiber lasers are produced in China, the cost of laser equipment has significantly decreased.

This cost advantage, like a powerful shock wave, quickly swept through the entire market. Laser equipment manufacturers can finally manufacture cost-effective laser marking machines, welding machines, and cutting machines. Both large factories and small workshops are able to afford laser equipment.

At this time, laser technology rapidly penetrated into countless industries.The applications include electronics, clothing, leather, gifts, hardware, and home appliances. Whether it’s marking on the phone case, welding the internal components of the phone, or cutting the metal shell, laser has become a “universal processing tool”.

Part 4: Further optimization of performance and reliability

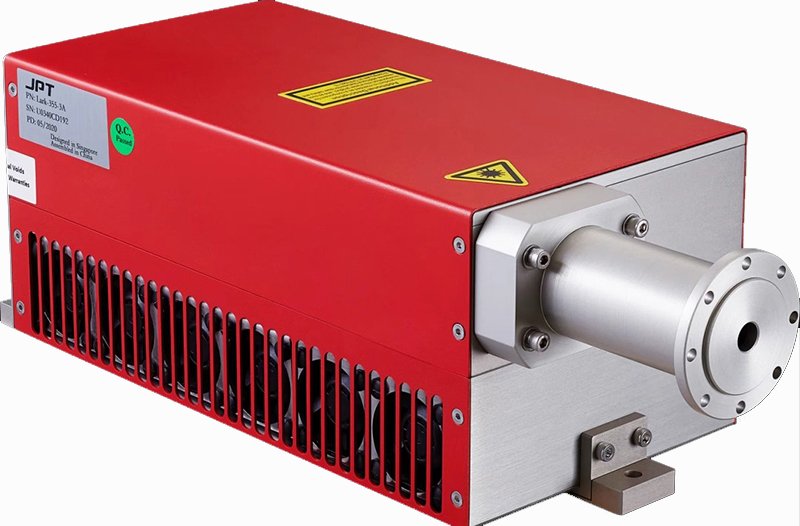

The early origin of fiber lasers in China had the advantage of being affordable. However, there is still a gap between it and top international products in terms of service life, light output stability, and beam quality. With the intensification of market competition and the increasing demands of users, Chinese enterprises are focusing on reliability and performance optimization.

They greatly improved the service life of fiber lasers by improving production processes, enhancing component quality, and optimizing control algorithms. The label of ‘cheap, no good’ has long been torn apart by the current low-medium power fiber lasers produced in China. Its stability and reliability can fully meet or even exceed the stringent requirements of industrial production.

Conclusion: The Silent Foundation

Looking back at the development history of low- to medium-power fiber lasers in China, they are not as eye-catching as the high-power “Ten Thousand Watt Fiber Lasers”. However, it is a significant journey that begins with cost control and culminates in quality improvement.