1 What are the types of laser spot welder ?

According to the laser emission principle, the welder can be divided into YAG laser spot welder machines and QCW laser spot welding machines.

- The YAG laser spot welding machine utilizes a xenon lamp (Nd: YAG). It generates a 1064nm laser, and its power can reach 500W.

- The QCW laser spot welding machine is a type of fiber laser welding machine. It uses optical fiber to emit a quasi-continuous wave (Quasi-CW) with high peak power.

2 How much power does a laser spot welding machine have?

For YAG laser spot welding machines, the commonly used powers are 150W, 200W, 300W, and 500W. The welding depth increases with the increase of power, and the maximum metal welding depth can reach 2mm.

For QCW laser spot welding machines, commonly used powers are 60W, 100W, 150W, 200W, and 300W. The welding depth can reach 3mm, and it has a high energy efficiency conversion rate.

3 What are the differences between laser spot welder?

Due to the different internal structures, the YAG laser spot welding requires a water-cooling module to solve the problem of overheating of the laser crystal rod during laser emission.

For laser welding machines with a power of 200W or less, an integrated design is often used, while for laser welding machines above 200W, a split water tank design is generally used.

The QCW laser spot welder does not require a water-cooling module and generally adopts an air-cooling design. Therefore, the QCW laser spot welder is lighter than the YAG type.

4 How to choose a suitable laser spot welder ?

A suitable laser spot welding machine can be selected based on our specific situation, and we can choose from the following aspects.

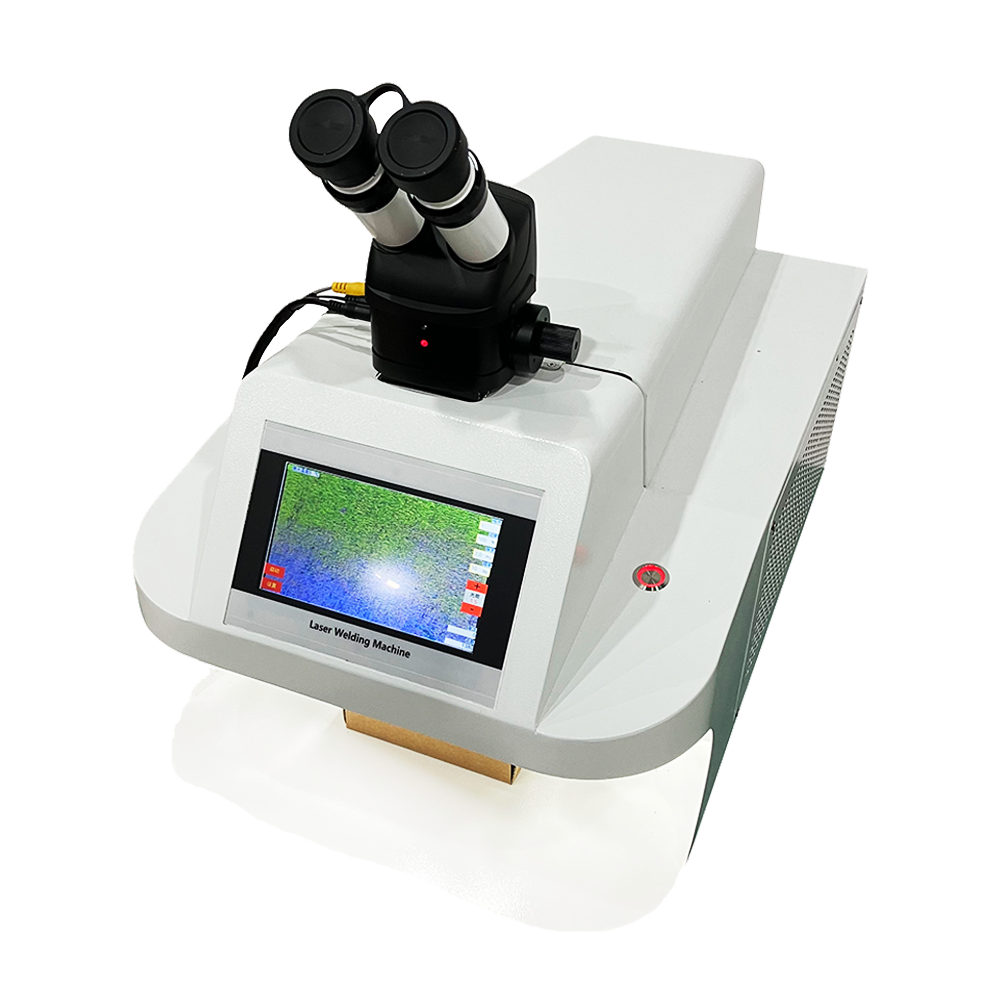

- Choose based on ease of use

We generally choose laser spot welders equipped with HD video and HD microscope observation systems, allowing for real-time monitoring of the welding progress on the welding platform.

- Choose based on cost-effectiveness

YAG laser welders are cheaper than QCW laser welders and offer higher cost-effectiveness.

- Choose based on the welding application

For applications in the medical, dental, and watchmaking industries, a QCW laser welder is recommended because it produces a smaller spot size and more aesthetically pleasing welds.