CO2 Beam Expander

A CO2 beam expander is an optical system consisting of two or more lenses. It’s primarily used to enlarge the diameter of a collimated beam while reducing its divergence angle. In a CO2 laser marking machine, it converts the laser output beam into a parallel beam of light. The parallel light is also known as a collimated beam.

1 Why do we need a CO2 beam expander?

After the laser is generated, it needs to be a collimated beam. Then, the laser can obtain a highly concentrated and extremely small focal spot through focusing (usually achieved by field lens devices). This is the foundation of laser marking, engraving, and welding machine.

2 Four principles for selecting a beam expander for CO2 marking machines.

The core issue to consider is matching. Ensure that the light beam in the optical path can be unobstructed and effectively utilized at every step.

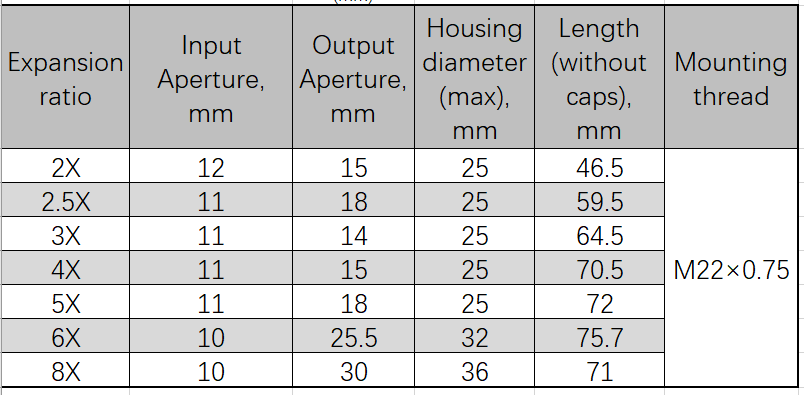

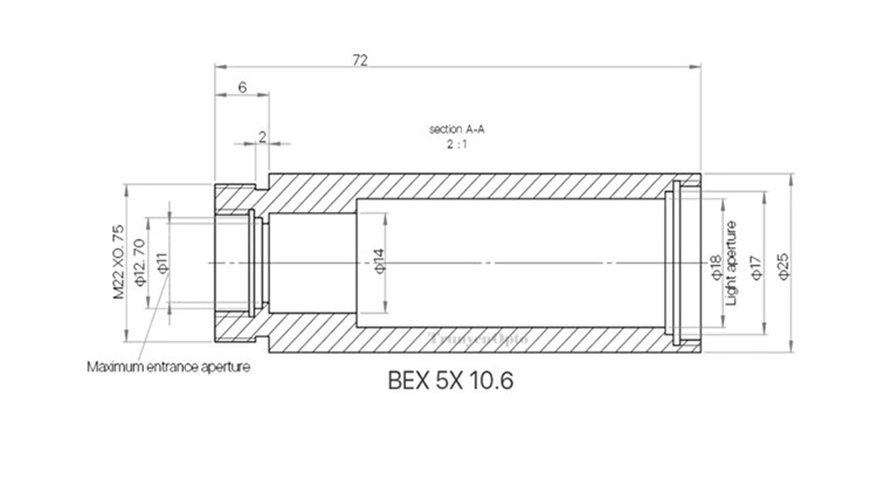

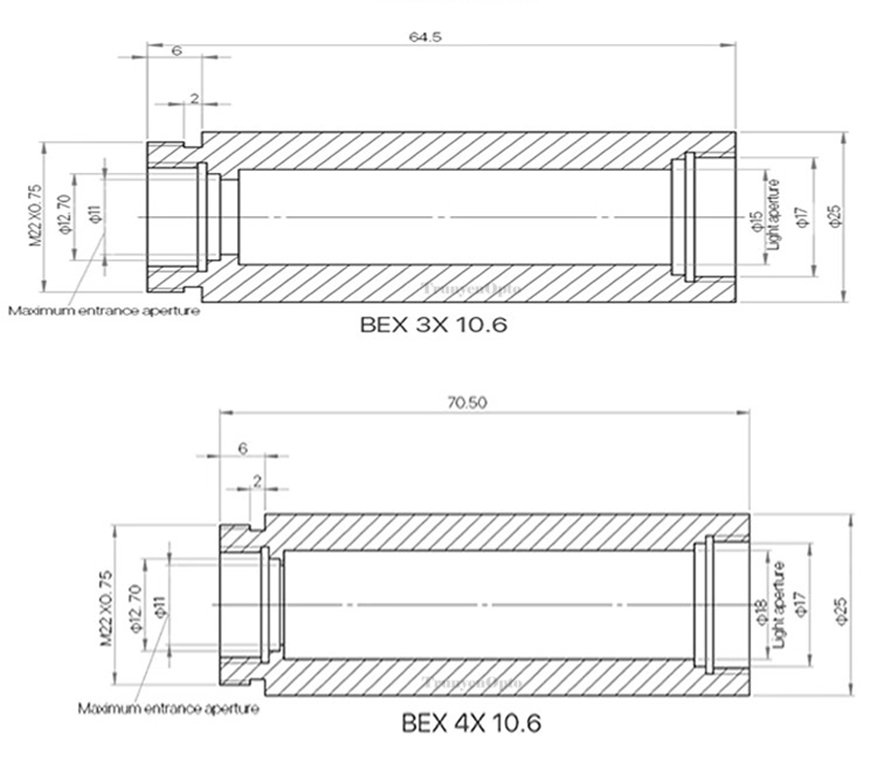

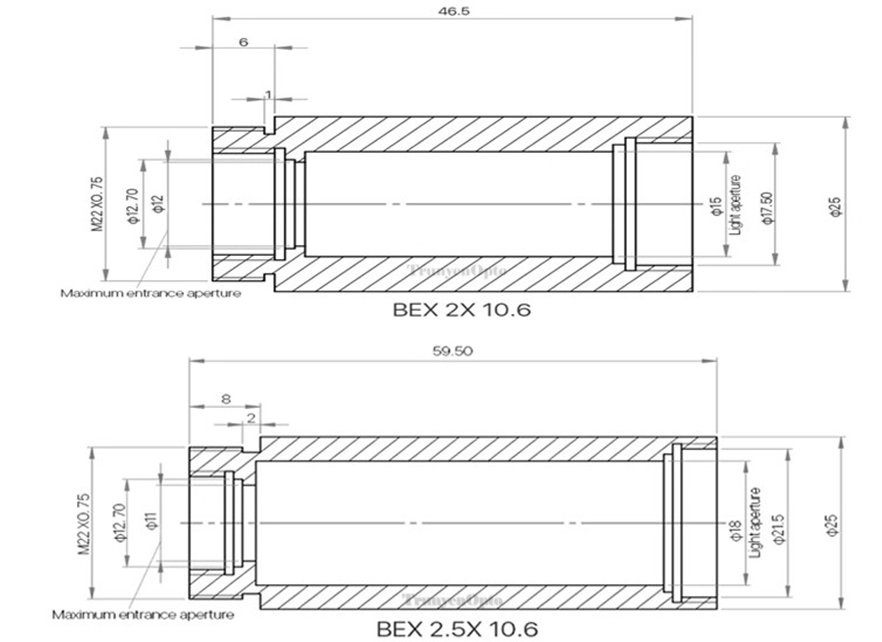

- Entrance matching. The incident aperture of the beam expander should be greater than or equal to the spot diameter of the incident laser. It can avoid energy loss and lens heating caused by cutting the beam.

- Export matching. The exit aperture of the beam expander should be greater than or equal to the diameter of the enlarged light spot after exit. It can avoid vignetting effects.

- Matching with the galvanometer. The enlarged spot diameter cannot exceed the effective aperture of the galvanometer lens. If the light spot is too large, the edge of the galvanometer lens will block some of the light, affecting the scanning accuracy and range.

- Match with field lens. The enlarged spot diameter should be less than or equal to the entrance pupil of the field lens. This is the most important point. If the spot size is larger than the entrance of the field lens, the field lens will not be able to receive all the light. Otherwise, the machine will not achieve the focused spot size and processing range.