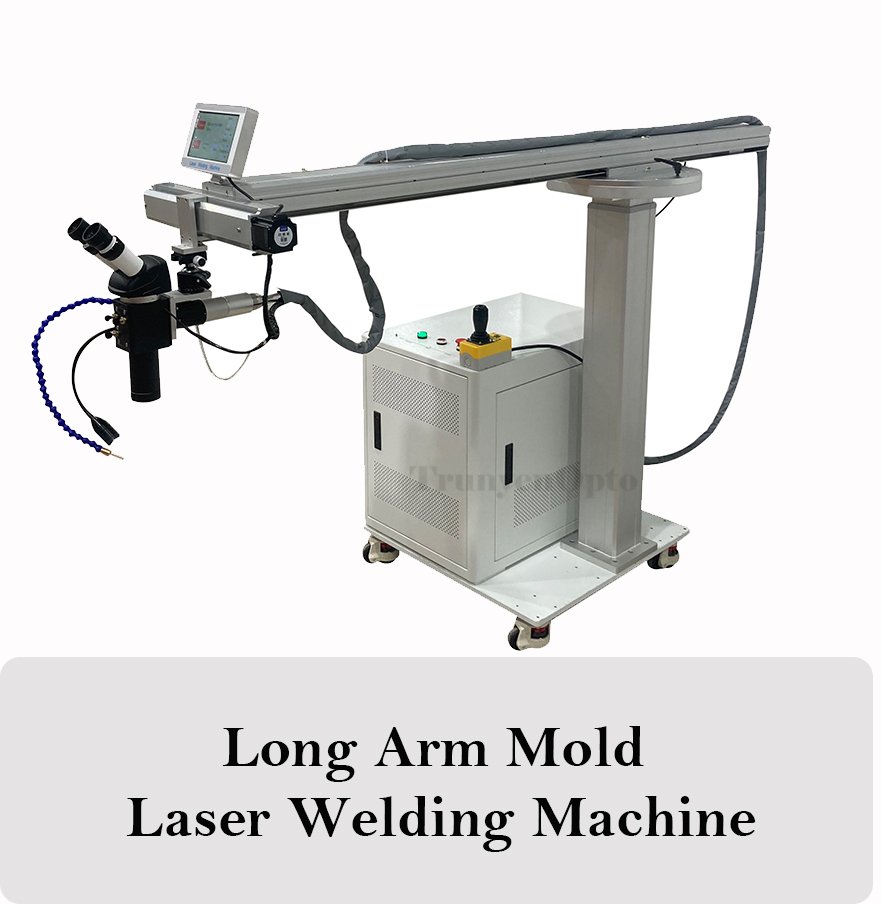

Mold Repair Laser Welding Machine For With 6-Aixs

What's the mold repair laser welding machine?

The mold repair laser welding machine gets precise melting and repair of metal materials through high-energy laser beams. It is particularly suitable for repairing various damages that occur during the usage of casting, stamping, and injection molds. The mold repair laser welder can efficiently repair casting defects (such as pores, slag holes, shrinkage holes), usability damage (such as cracks, fractures, angular wear), and sand holes. It can extend the service life of high-value molds.

1 The diameter of the laser beam can be precisely controlled to the micrometer level. It can repair thin-walled parts, complex curved surfaces, and precision cutting edges that cannot be processed by traditional welding (such as cold work die tough edges and tool cutting edges), avoiding deformation or annealing problems caused by thermal stress in workpieces, especially suitable for high melting point and high hardness special materials (such as high-speed steel and hard alloys).

2 Breaking through traditional repair methods:

- No need for preheating or post-heating treatment. Direct cold welding avoids material structure phase transformation and maintains substrate hardness.

- Vacuum environment adaptability: supports operation in protective atmospheres or vacuum chambers to prevent oxidation.

- Instant repair: Eliminating the several hours of preheating and insulation process required for argon arc welding, increasing efficiency by over 80%.

3 Material compatibility and performance restoration. Widely applicable to common mold materials such as ductile iron, gray cast iron, stainless steel, alloy steel, etc. The repaired area can achieve mechanical properties consistent with the substrate by the homogeneous welding materials.

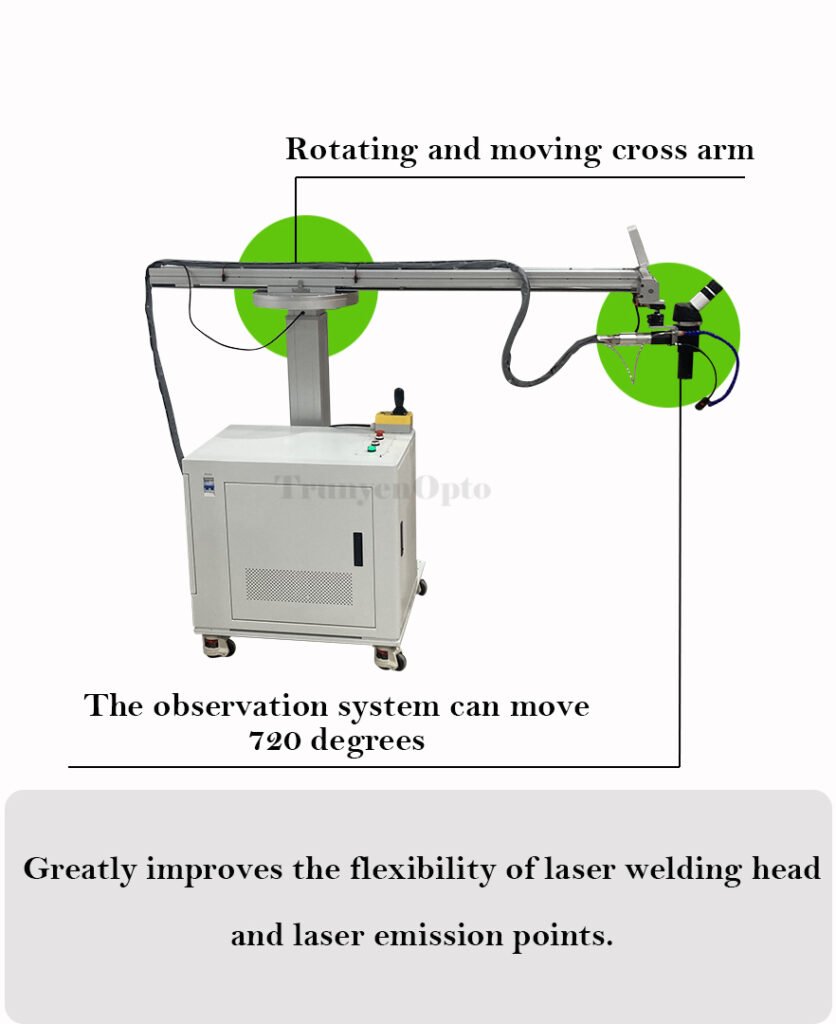

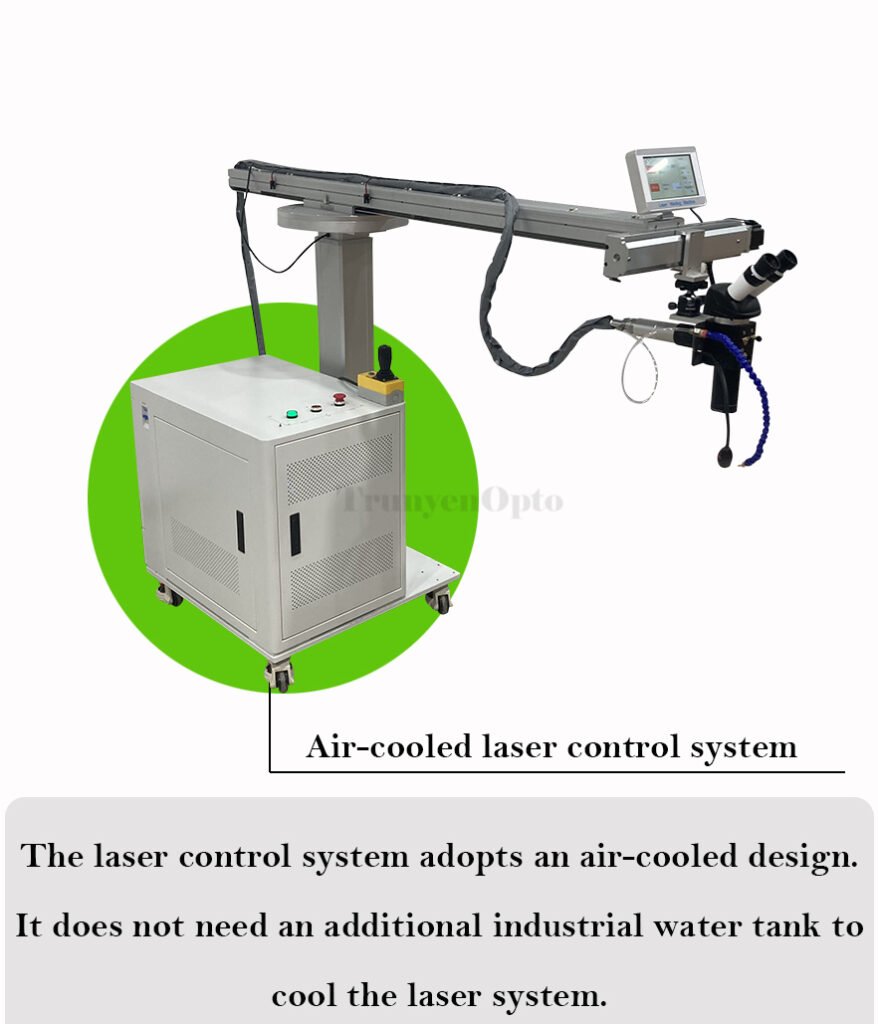

Details of mold repair laser welding machine: